Auto Nesting

Run all fabrication machines from one powerful software platform that scales with your need

CAD/CAM Nesting solution for 2D or bevel profile cutting, routing, or punching premium quality parts using less material

CAD/CAM Nesting solution for cutting tube, pipe, and structural steel within 3D SOLID WORKS and environment.

Intuitive 3D Press Brake solution for offline verification and accelerated production.

Optimized Cut-to-Length Nesting for miter and bundle cutting of bar, tube, pipe, and beam stock

Integrated Unfolding Interface that recognizes bend features and flattens with K-factor accuracy

DSTV Exporter Plugin to seamlessly generate NC1 files within SOLIDWORKS

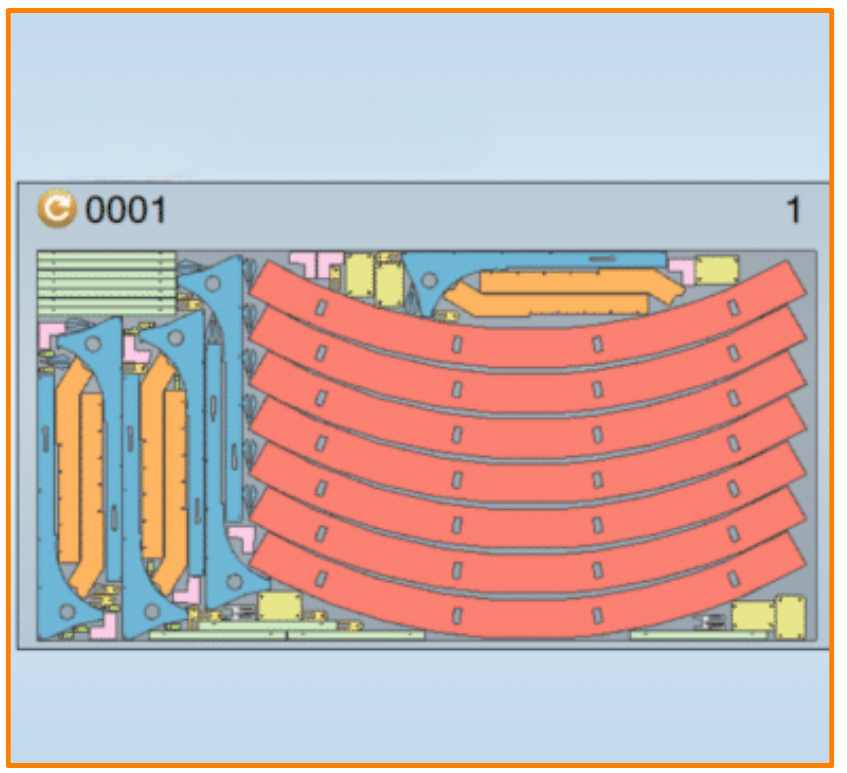

Irregular Shape Nesting

Auto Nesting

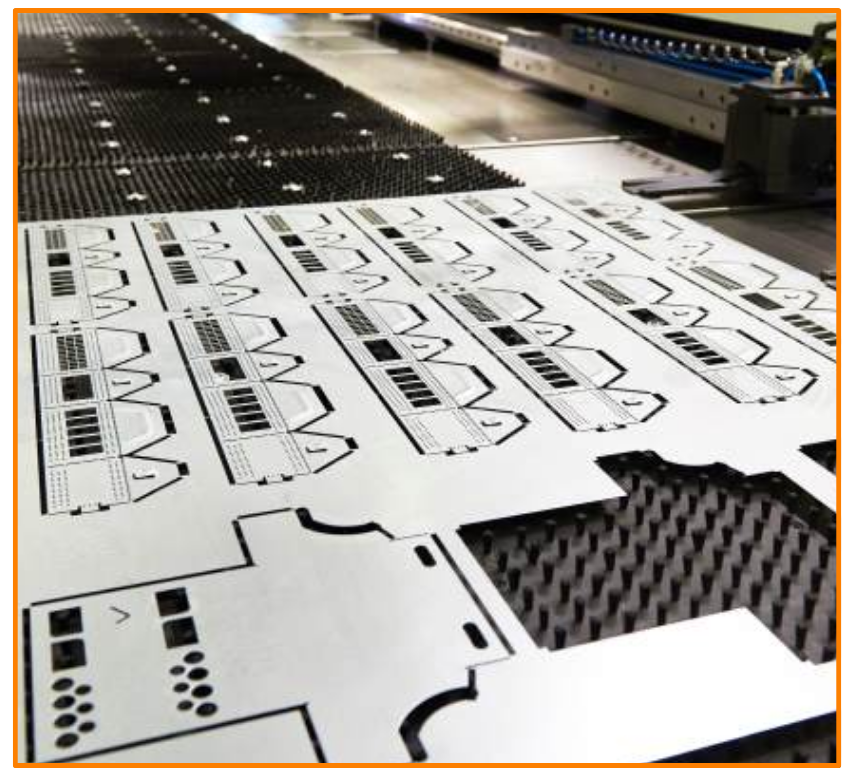

MaxxCAM’s irregular nesting engine allows nesting on multiple sheets and sizes simultaneously, resulting in stunning results.

Irregular nesting features included:

Rotation and grain control

Nest for next process

Due date nesting

Priority of parts

Mirror of parts

Revision of parts

Nesting of parts and assemblies

Comprehensive reports

Colour code for easy part identification

Use of multi-core processors for fast results

Rectangular Nesting

Rectangular nesting will treat any shape as a rectangle, which is why it is called rectangular nesting.

MaxxCAM’s rectangular nester will allow nesting on multiple sheets and sizes at the same time, resulting in stunning results.

Rectangular nesting features include:

Rotation and grain control

Nest for next process

Due date nesting

Priority of parts

Mirror of parts

Revision of parts

Nesting of parts and assemblies

Comprehensive reports

Colour code for easy part identification

Use of multi-core processors for fast results