Punch CAM

Run all fabrication machines from one powerful software platform that scales with your need

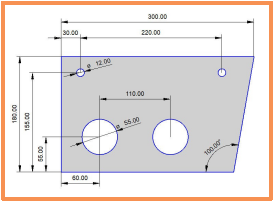

CAD/CAM Nesting solution for 2D or bevel profile cutting, routing, or punching premium quality parts using less material

CAD/CAM Nesting solution for cutting tube, pipe, and structural steel within 3D SOLID WORKS and environment.

Intuitive 3D Press Brake solution for offline verification and accelerated production.

Optimized Cut-to-Length Nesting for miter and bundle cutting of bar, tube, pipe, and beam stock

Integrated Unfolding Interface that recognizes bend features and flattens with K-factor accuracy

DSTV Exporter Plugin to seamlessly generate NC1 files within SOLIDWORKS

Punch CAM

The MaxxCAM tooling engine provides the best automated and interactive capabilities available in the industry.

CAM features include

Automatic tooling & interactive tooling

Automatic placement of micro-joint

Automatic tooling of special shapes

Automatic tooling of special shapes

Automatic tooling of countersink, tapping, forming

Automatic Wilson Wheel support

Automatic part removal by chute or picker device

Automatic optimisation of travel path

Automatic feed rate control

Automatic repositioning

Automatic part ID tooling

Graphical turret loading

Cost estimation for parts and nests

MaxxCAM Sequencer

"Getting tired of clicking with that mouse??"

Sequencing is one of the toughest challenges in sheetmetal fabrication.

We have have accepted the challenge and believe that we have the best sequencing strategies in the industry,

Sequencing features include:

Auto or interactive sequencing

Sequencing rules can be set

Automatic form avoidance

Travel paths are highly optimised

Auto reposition / sheet flip & turn

Auto clamp positioning

Simulation of NC code

Sheet trimming

Run time estimation